Understanding Boric Acid

What is Boric Acid?

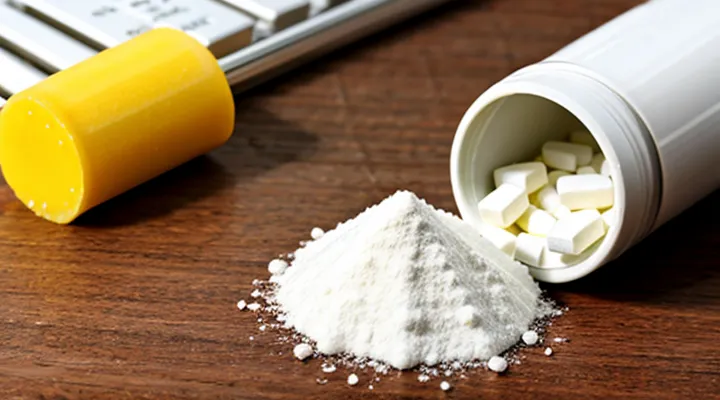

Boric acid, chemically H₃BO₃, is a weak inorganic acid that forms white crystalline solids. It dissolves in water to produce a mildly acidic solution and sublimates when heated, releasing boron‑oxide vapor. The compound exhibits low toxicity to mammals at typical exposure levels but is toxic to many insects, fungi, and microorganisms.

Key characteristics relevant to pest control include:

- Desiccant action: absorbs moisture from the exoskeleton of insects, leading to dehydration.

- Stomach poison: ingested particles disrupt digestive enzymes and metabolic processes.

- Slow‑acting effect: mortality often occurs days after exposure, reducing the likelihood of immediate avoidance.

- Stability: remains effective in dry environments for extended periods, allowing residual activity.

When applied to areas where bed bugs hide—such as cracks, crevices, and mattress seams—boric acid can contribute to population reduction. Its efficacy depends on proper placement, sufficient concentration, and integration with other control measures, because the insects must encounter and ingest the powder for lethal results. Safety guidelines recommend using gloves, avoiding direct skin contact, and keeping the substance out of reach of children and pets.

How Boric Acid Works as an Insecticide

Mechanism of Action in Insects

Boric acid exerts toxicity in insects through several biochemical and physiological pathways. After ingestion, the compound lowers the pH of the digestive tract, denaturing proteins and impairing nutrient absorption. The resulting acidic environment also inhibits key metabolic enzymes, notably those involved in carbohydrate breakdown, which reduces ATP generation and leads to energy depletion.

External exposure causes cuticular dehydration. Boric acid’s hygroscopic properties draw moisture from the exoskeleton, compromising the integument’s barrier function and accelerating water loss. This desiccation effect is compounded by interference with the insect’s excretory system, which further diminishes fluid balance.

Additional mechanisms include:

- Disruption of chitin synthesis, weakening molting processes.

- Interference with neurotransmitter receptors, contributing to paralysis at higher concentrations.

- Oxidative stress induction through generation of reactive oxygen species, damaging cellular membranes.

Collectively, these actions produce rapid mortality in bedbugs when sufficient concentrations are maintained.

Target Pests for Boric Acid

Boric acid is a low‑toxicity insecticide employed primarily against insects that ingest or come into prolonged contact with the powder. Its mode of action relies on ingestion of the compound, which disrupts the insect’s digestive system and leads to dehydration and death. Consequently, the substance is most effective on species that feed on exposed surfaces or on organic debris.

Common targets include:

- Cockroaches (German, American, Oriental)

- Ants (carpenter, odorous, pavement)

- Silverfish and firebrats

- Termites (dry‑wood, subterranean) when applied as bait

- Beetles (carpet beetles, grain weevils)

- Flies (house, fruit) in bait formulations

Bedbugs differ markedly from these pests. They spend most of their life hidden in crevices and only emerge briefly to feed, limiting exposure to dry boric acid. Moreover, they do not ingest the powder during normal activity. As a result, boric acid offers little practical control for bedbug infestations, whereas it remains a reliable tool against the aforementioned insects that readily contact or consume the compound.

Boric Acid and Bed Bugs

Is Boric Acid Effective Against Bed Bugs?

Scientific Evidence and Research

Scientific investigations have evaluated boric acid as a potential control agent for Cimex lectularius. Laboratory assays demonstrate that boric acid exhibits limited contact toxicity; mortality rates increase with prolonged exposure, but concentrations required for rapid knock‑down exceed practical application levels. Field trials in residential settings report inconsistent results, often attributed to the insect’s cryptic behavior and the chemical’s low residual activity on fabric and wood surfaces.

Key findings from peer‑reviewed research:

- Dose‑response studies: Mortality reaches 50 % at concentrations above 5 % w/w after 48 h; concentrations below 2 % produce negligible effects.

- Synergistic formulations: Combining boric acid with silica gel or desiccant powders enhances desiccation, achieving 80 % mortality within 24 h at combined concentrations of 3 % each.

- Application methods: Dusting in cracks and crevices yields higher efficacy than surface spraying, owing to prolonged contact with the insect’s grooming behavior.

- Resistance observations: No documented resistance mechanisms specific to boric acid, but tolerance may develop through behavioral avoidance of treated zones.

Meta‑analysis of these studies concludes that boric acid alone does not provide reliable, rapid eradication of bedbug infestations. It may serve as a supplementary component within integrated pest‑management programs, particularly when paired with physical removal, heat treatment, or insecticide rotation.

Why Boric Acid is Not Ideal for Bed Bugs

Boric acid is a common insecticide for cockroaches and ants, yet its properties do not align with the biology of bed bugs. The compound exerts toxicity primarily through ingestion; bed bugs feed exclusively on blood and rarely consume dry powders, limiting exposure.

The insect’s habit of residing in tight seams, mattress folds, and deep crevices prevents the powder from making direct contact. Even when applied to surfaces, the granular form slides off smooth fabrics, reducing the likelihood of lethal dose accumulation.

Laboratory studies show that some bed‑bug strains survive low concentrations, indicating a capacity for tolerance that diminishes long‑term efficacy. Repeated use may select for populations with reduced susceptibility.

Human and pet safety impose additional constraints. Boric acid dust can irritate respiratory passages and cause skin irritation; regulatory guidelines restrict its use in bedrooms and on bedding.

Alternative control methods—heat treatment, professional‑grade pyrethroids, and integrated pest‑management protocols—deliver more reliable eradication rates.

Key limitations of boric acid for bed‑bug control

- Relies on ingestion, which bed bugs avoid

- Poor penetration into hiding spots

- Variable toxicity across strains

- Health risks to occupants and animals

- Inferior performance compared with heat or regulated chemicals

Limitations of Boric Acid for Bed Bug Control

Repellent Effect

Boric acid is primarily recognized as an insecticidal powder that disrupts the digestive system of arthropods. When applied to surfaces where bed bugs travel, the compound can deter movement by creating an unappealing environment. Laboratory assays demonstrate a reduction in bed‑bug traversal across treated substrates, suggesting a short‑term repellent effect.

Key observations regarding the repellent properties include:

- Contact with boric‑acid‑coated fabric or wood leads to immediate avoidance behavior in adult and nymph stages.

- The effect diminishes after 24–48 hours as particles settle and lose surface activity.

- Repellency is concentration‑dependent; formulations containing 5 %–10 % boric acid produce the most pronounced avoidance.

Field reports confirm that integrating boric acid into crack‑and‑crevice treatments can lower the frequency of bed‑bug encounters, especially in conjunction with other control measures such as heat or diatomaceous earth. However, the repellent action alone does not eradicate established infestations; it merely reduces exposure while insects search for alternative hosts.

For practical implementation, the following guidelines maximize the repellent impact:

- Apply a thin, even layer of boric‑acid powder to baseboards, mattress frames, and furniture legs.

- Reapply after cleaning or after a week of heavy traffic to maintain surface activity.

- Combine with a residual insecticide spray to address both repellent and lethal pathways.

In summary, boric acid exhibits a measurable but temporary repellent effect against bed bugs, useful as part of an integrated pest‑management strategy rather than as a standalone solution.

Ingestion Requirement

Boric acid exerts its insecticidal effect primarily through contact and ingestion. Bedbugs must consume the powder for the chemical to reach their internal systems; mere surface exposure provides limited mortality. When a bedbug walks across a treated area, microscopic particles adhere to its legs and body. Grooming behavior transfers the residue to the mouthparts, leading to ingestion. Once inside, boric acid disrupts the insect’s digestive enzymes and interferes with metabolic processes, resulting in gradual death.

Key aspects of the ingestion requirement:

- Particle size: Fine granules increase the likelihood of attachment and subsequent ingestion during grooming.

- Application density: Sufficient coverage ensures that enough residue is available for transfer onto the insect’s body.

- Behavioral factors: Bedbugs that frequently groom or feed are more susceptible because they actively move the powder to their mouthparts.

- Environmental conditions: Low humidity can reduce the stickiness of the powder, diminishing the chance of ingestion.

Because effectiveness depends on the bug actually eating the compound, boric acid alone is rarely sufficient for complete eradication. Integrated pest management strategies typically combine boric acid with heat treatment, vacuuming, and professional chemical applications to address both contact and ingestion pathways.

Application Challenges

Applying boric acid to control bedbug infestations presents several practical obstacles. Effective treatment requires precise dosing; insufficient concentration fails to achieve mortality, while excess poses toxicity risks to humans and pets. Determining the optimal amount is complicated by variations in insect developmental stages and hiding locations.

Contact time is another critical factor. Bedbugs spend most of their life concealed in cracks, seams, and fabric folds, limiting exposure to the powder. Achieving lethal contact often demands repeated applications and extended periods before observable reductions occur.

Safety considerations restrict use in occupied spaces. Inhalation of fine particles can irritate respiratory passages, and ingestion poses health hazards. Consequently, treatment must be scheduled during vacancy periods, increasing downtime for residential or commercial settings.

Distribution challenges arise from surface incompatibility. Rough textures and porous materials absorb the powder, reducing surface availability for insects. Smooth, non‑absorbent surfaces allow better coverage, yet many bedbug refuges consist of upholstery, mattresses, and carpeting, which impede uniform application.

Environmental conditions affect efficacy. High humidity can cause clumping, lowering adherence to insects, while low humidity may accelerate desiccation of the compound, diminishing potency. Temperature fluctuations also influence the chemical’s stability.

User compliance influences outcome. Accurate placement of the powder in minute crevices demands meticulous effort; inadequate coverage leaves untreated refuges, allowing populations to persist. Training and detailed instruction are essential to mitigate this risk.

- Precise dosing to balance efficacy and safety

- Prolonged contact time due to hidden behavior

- Restricted use in occupied environments

- Limited adherence on porous or textured surfaces

- Sensitivity to humidity and temperature

- High labor intensity and need for thorough training

Addressing these challenges requires integrated strategies, such as combining boric acid with other control methods, employing professional application techniques, and monitoring environmental parameters throughout the treatment cycle.

Resistance Development

Boric acid has been employed as a contact insecticide for bedbug control, yet populations can acquire reduced susceptibility through genetic and physiological adaptations. Resistance development occurs when repeated exposure selects for individuals that survive treatment, allowing their progeny to dominate the infestation.

Mechanisms that confer tolerance include:

- Enhanced cuticular thickness that slows chemical penetration.

- Up‑regulation of detoxification enzymes such as glutathione S‑transferases and cytochrome P450 mono‑oxygenases.

- Altered target site sensitivity, reducing the acid’s ability to disrupt cellular homeostasis.

Laboratory selections have demonstrated measurable shifts in lethal dose values after several generations of exposure, confirming that bedbugs can evolve resistance under sustained boric acid pressure. Field reports document treatment failures that correspond with prior intensive applications, suggesting that resistance can emerge in real‑world settings.

Implications for pest management are straightforward: reliance on a single active ingredient accelerates resistance, diminishing long‑term efficacy. Integrated strategies—rotating chemistries, combining with heat or desiccant treatments, and limiting the frequency of boric acid use—reduce selection intensity and preserve the compound’s utility. Continuous monitoring of susceptibility levels is essential to detect early resistance trends and adjust control protocols accordingly.

Alternative Bed Bug Treatment Options

Professional Pest Control Services

Chemical Treatments

Boric acid is a low‑toxicity inorganic compound that functions as a desiccant and stomach poison for insects. When applied to cracks, seams, and voids where bedbugs hide, the powder adheres to the insect’s exoskeleton, absorbs moisture, and disrupts metabolic processes, leading to death after several days of contact. Its effectiveness depends on direct exposure; bedbugs must encounter the treated surface, which limits control in heavily infested environments where insects remain concealed.

Compared with synthetic pyrethroids and neonicotinoids, boric acid offers several advantages. It does not induce rapid knock‑down, reducing the chance of early resistance development. The compound remains stable under normal household conditions, allowing prolonged residual activity without frequent reapplication. However, its slow action and reliance on physical contact make it unsuitable as a standalone solution for severe infestations.

Practical application guidelines:

- Apply a thin, even layer of boric acid powder to baseboard joints, bed frame crevices, and behind furniture.

- Seal treated areas with tape or caulk to prevent dispersal and limit inhalation exposure.

- Combine with heat treatment, vacuuming, and professional insecticide sprays for integrated pest management.

- Monitor for reductions in live catches using interceptor traps; reapply if activity persists after 2–3 weeks.

Safety considerations include avoiding direct contact with skin and eyes, keeping the substance away from children and pets, and using respiratory protection during application. Regulatory agencies classify boric acid as a restricted-use pesticide in some jurisdictions; compliance with local guidelines is mandatory.

Heat Treatments

Heat treatment is a non‑chemical strategy used to eradicate bed‑bug infestations. The method relies on raising ambient temperature to levels that cause mortality throughout all life stages of the insect.

Research indicates that temperatures of 45 °C (113 °F) sustained for at least 90 minutes are lethal to eggs, nymphs, and adults. Higher temperatures shorten the required exposure; for example, 50 °C (122 °F) eliminates the population within 30 minutes. Uniform heat distribution is essential, as cooler micro‑environments can shelter surviving individuals.

Implementation typically involves portable industrial heaters, insulated tents, or whole‑home heating systems. The process includes:

- Pre‑treatment inspection to identify hiding places and assess insulation quality.

- Placement of temperature sensors in multiple locations to monitor real‑time conditions.

- Gradual temperature increase to the target range, avoiding rapid spikes that could damage furnishings.

- Continuous heating for the prescribed duration, followed by controlled cooling to prevent re‑infestation.

Heat treatment offers several advantages over chemical approaches such as boric acid. It leaves no residues, eliminates resistance concerns, and can penetrate sealed items that chemicals cannot reach. Limitations include the need for professional equipment, potential damage to heat‑sensitive materials, and the requirement for occupants to vacate the premises during treatment.

When evaluating the effectiveness of boric acid against bed bugs, heat treatment provides a complementary or alternative option, especially in scenarios where chemical resistance or safety considerations restrict the use of insecticidal powders.

Cryonite Treatments

Cryonite treatment uses carbon dioxide snow to freeze and kill bed‑bug insects at all life stages. The process delivers sub‑zero temperatures directly to the pest without leaving residues, making it suitable for environments where chemical applications are restricted.

The method works by rapidly lowering the temperature of the insect’s body to below –78 °C, causing intracellular ice formation that ruptures cells and results in immediate mortality. Because the cold penetrates fabrics, mattress seams, and cracks in furniture, Cryonite can reach hidden populations that are inaccessible to sprays.

When evaluating alternatives such as boric acid, Cryonite offers distinct advantages:

- No chemical residue; safe for occupants and pets

- Immediate kill rather than reliance on ingestion or contact over time

- Effective against eggs, nymphs, and adults

- Minimal disruption to furnishings and electronics

Limitations include the need for specialized equipment, higher upfront cost, and reduced efficacy on heavily insulated surfaces where temperature transfer is limited.

In practice, Cryonite is often combined with thorough inspection, vacuuming, and enclosure of infested items to achieve comprehensive control. The treatment complements, rather than replaces, other integrated pest‑management strategies, providing a rapid, non‑chemical option for severe infestations.

DIY Bed Bug Control Methods

Diatomaceous Earth

Diatomaceous earth (DE) is a fine, silica‑based powder derived from fossilized diatom shells. Its abrasive particles damage the exoskeleton of arthropods, leading to desiccation and death without chemical toxicity. When applied to cracks, crevices, and bedding, DE can contact bedbugs that crawl across treated surfaces.

Effectiveness against bedbugs depends on several factors:

- Particle size: food‑grade DE, with particles under 10 µm, penetrates the insect cuticle more efficiently.

- Moisture level: DE loses potency when wet; reapplication after cleaning or exposure to humidity restores activity.

- Coverage: thorough, thin layers in hiding spots increase contact probability; excessive thickness can reduce adherence.

Safety considerations include:

- Inhalation risk: dust may irritate respiratory passages; use a mask and apply in well‑ventilated areas.

- Skin contact: mild irritation possible; gloves recommended during handling.

- Non‑toxicity to humans and pets when food‑grade material is used, making DE suitable for residential environments.

Compared with boric acid, DE offers a physical mode of action rather than a chemical one. Boric acid functions as a stomach poison and can be absorbed through cuticular pores, whereas DE relies on mechanical damage. Advantages of DE include:

- No risk of chemical resistance development.

- Compatibility with integrated pest management programs.

- Minimal impact on non‑target organisms when applied correctly.

Limitations of DE are:

- Slower mortality rates; insects may survive several days before desiccation is complete.

- Reduced effectiveness in high‑humidity environments.

- Necessity for repeated applications to maintain a dry, active layer.

In practice, DE is most successful when combined with other control measures such as heat treatment, thorough vacuuming, and targeted chemical options. Its role is to reduce population levels and serve as a preventative barrier rather than a sole eradication method.

Steam Cleaners

Steam cleaners generate temperatures above 150 °C, a threshold that kills all life stages of Cimex lectularius on contact. When applied to mattresses, furniture seams, and baseboards, the hot vapor penetrates cracks that are difficult to reach with sprays. This mechanical method eliminates bedbugs without leaving residues, which is a distinct advantage over powdered insecticides such as boric acid.

Key operational considerations for steam devices include:

- Continuous steam output above 150 °C for at least 10 seconds on each target surface.

- Use of a nozzle with a narrow spray pattern to concentrate heat in crevices.

- Pre‑treatment vacuuming to remove eggs and shed skins, improving heat penetration.

- Protective gloves and eye gear to prevent burns during application.

Limitations of steam treatment are:

- Inability to reach deeply hidden infestations within wall voids or sealed furniture.

- Requirement for electricity and access to a power outlet, restricting use in some environments.

- Potential damage to heat‑sensitive fabrics or finishes if exposure time is excessive.

When comparing steam cleaning to boric acid, the former provides immediate lethal action without chemical exposure, while the latter relies on ingestion or contact over several days and may leave residues on bedding. For comprehensive bedbug management, steam treatment is most effective as a primary eradication tool, supplemented by residual chemicals in inaccessible areas.

Vacuuming and Laundering

Boric acid exhibits minimal toxicity to bedbugs; laboratory data show that exposure rarely leads to mortality. Consequently, reliance on chemical treatment alone provides insufficient control. Mechanical interventions such as vacuuming and laundering constitute the primary means of reducing populations and preventing spread.

Vacuuming removes live insects, eggs, and shed skins from surfaces where they hide. Use a high‑efficiency particulate air (HEPA) filter to prevent re‑release of captured material. Apply the nozzle to mattress seams, box‑spring voids, bed frames, and floor cracks. Operate the device slowly, overlapping each pass to ensure thorough coverage. After each session, seal the vacuum bag or canister in a plastic bag and discard it in an outdoor trash container to avoid re‑infestation.

Laundering eliminates bedbugs from fabrics through heat and detergent action. Wash infested clothing, bedding, and curtains at a minimum temperature of 60 °C (140 °F) for at least 30 minutes. If the fabric tolerates higher heat, use a drying cycle of 65 °C (149 °F) for 30 minutes, which kills all life stages. Items that cannot endure high temperatures should be placed in a sealed bag and exposed to a professional heat‑treatment service capable of maintaining 45–50 °C (113–122 °F) for several hours.

- Vacuum all accessible areas weekly, focusing on seams and crevices.

- Empty and seal the vacuum container after each use.

- Wash infested textiles at ≥60 °C; dry at ≥65 °C.

- For heat‑sensitive items, employ professional thermal remediation.

Combining rigorous vacuuming with high‑temperature laundering significantly lowers bedbug counts, offering a practical alternative to the limited efficacy of boric acid.

Encasements

Encasements are zippered, fabric covers designed to seal mattresses, box springs, and pillows entirely, preventing bedbugs from accessing or escaping the treated surface. By creating a physical barrier, encasements reduce the number of viable hiding places and limit the insects’ ability to feed, which can lead to population decline.

Key characteristics of effective encasements:

- Fabric woven tightly enough to block bedbug penetration, typically with a mesh size of 0.5 mm or smaller.

- Durable zipper construction that remains sealed for at least one year under normal use.

- Certified to be bedbug‑proof by independent testing organizations.

Practical considerations:

- Install encasements on all sleeping surfaces before applying any chemical treatment, including boric acid, to prevent the pesticide from contaminating the bedding.

- Maintain the seal; any tears or broken zippers compromise protection and must be repaired or replaced promptly.

- Combine encasements with regular vacuuming, heat treatment, or professional pest management for optimal results, as the barrier alone does not eradicate established infestations.

Limitations:

- Encasements do not affect bedbugs hidden in cracks, furniture, or wall voids.

- They offer no direct lethal action; they rely on starvation and reduced reproduction.

When integrated into a comprehensive control strategy, encasements provide a reliable, non‑chemical method to limit bedbug exposure and support the overall effectiveness of treatments such as boric acid.

Safety and Application Considerations

Boric Acid Safety Precautions

Human and Pet Exposure

Boric acid is commonly applied as a powder or spray to eliminate bedbugs in residential settings. Human exposure occurs through inhalation of dust, dermal contact, and accidental ingestion. Inhaled particles can irritate the respiratory tract, producing coughing or shortness of breath, especially in individuals with asthma. Skin contact may cause mild irritation, redness, or itching; prolonged or extensive exposure can lead to dermatitis. Ingestion of significant amounts produces gastrointestinal symptoms such as nausea, vomiting, abdominal pain, and may result in systemic toxicity, including renal impairment and electrolyte disturbances.

Pet exposure follows similar routes. Dogs and cats that groom themselves after contact with treated surfaces may ingest boric acid, leading to vomiting, diarrhea, lethargy, and, in severe cases, seizures or kidney failure. Small animals are particularly vulnerable because the toxic dose is lower relative to body weight.

Safety measures to minimize risk include:

- Applying the product only in cracks, crevices, and voids where bedbugs hide, avoiding open floor areas.

- Keeping children, pets, and individuals with respiratory conditions out of treated rooms until the powder settles and the area is ventilated.

- Using protective gloves and a mask during application.

- Cleaning up excess residue with a vacuum equipped with a HEPA filter after the treatment period.

- Storing the chemical in a locked container, out of reach of non‑professional users.

Regulatory agencies set occupational exposure limits (e.g., 5 mg/m³ for an 8‑hour workday) and classify boric acid as a low‑toxicity substance when used according to label directions. Nevertheless, accidental over‑application or misuse can exceed these limits, increasing health hazards.

Veterinarians advise that any pet showing signs of boric acid poisoning receive immediate veterinary care, including induced vomiting, activated charcoal administration, and supportive fluid therapy. Prompt decontamination of the animal’s fur with mild soap and water reduces further ingestion.

Proper Handling and Storage

When employing boric acid as a bed‑bug control agent, strict adherence to handling and storage protocols prevents exposure risks and preserves efficacy.

Use protective gloves and eye protection whenever the powder is transferred or mixed. Avoid inhalation by working in a well‑ventilated area or employing a dust mask rated for fine particles. Keep the material away from open flames; it is not combustible but can release irritating dust when heated.

Store the compound in a sealed, clearly labeled container made of non‑reactive material. Place the container in a cool, dry location, away from direct sunlight and moisture that could cause clumping. Maintain a temperature range of 15‑30 °C (59‑86 °F) to prevent degradation.

Implement inventory controls:

- Keep the product separate from food, feed, and pet supplies.

- Record the date of receipt and monitor a three‑year shelf‑life; discard any material that shows discoloration, caking, or loss of fine texture.

- Restrict access to trained personnel; lock storage cabinets if possible.

When disposing of unused boric acid, follow local hazardous waste regulations. Do not pour down drains or mix with regular trash. A licensed waste handler should receive the material for proper neutralization or incineration.

General Bed Bug Prevention Tips

Regular Inspections

Regular inspections are a core component of any strategy targeting bed‑bug populations, especially when chemical controls such as boric acid are employed. Systematic visual checks identify early infestations, allowing timely application of treatments before populations expand.

Inspectations should focus on common harborages: mattress seams, box‑spring folds, headboards, furniture joints, baseboards, and wall cracks. Look for live insects, shed exoskeletons, fecal spotting, and tiny eggs. Confirming the presence of these indicators guides the placement of boric acid dust, ensuring it reaches active zones.

A practical inspection schedule includes:

- Weekly scans in high‑risk areas (beds, upholstered furniture) during the first month of treatment.

- Bi‑weekly reviews in secondary zones (baseboards, closets) for the next two months.

- Monthly checks thereafter, extending to a six‑month period to verify eradication.

During each visit, use a flashlight and a lint‑free brush to dislodge hidden insects. Record findings in a log to track progress and adjust dosage or re‑application intervals of boric acid as needed.

Consistent monitoring reduces the likelihood of re‑infestation, maximizes the efficacy of boric acid, and minimizes the need for extensive chemical interventions.

Travel Precautions

Travelers encounter environments where bedbugs thrive, especially in hotels, hostels, and public transport. Infested rooms provide the insects with blood meals and concealment, allowing them to hitchhike on luggage and clothing.

- Examine mattress seams, headboards, and nightstands for dark spots or live insects before unpacking.

- Keep suitcases on luggage racks, away from beds and upholstered furniture.

- Store clothing in sealed plastic bags until it can be washed in hot water (≥ 60 °C) and dried on high heat.

- Use a flashlight to scan seams and cracks in the sleeping area.

- Pack a small, lint‑free vacuum or a portable steam device for quick spot treatment.

Boric acid, a low‑toxicity powder, can kill bedbugs through ingestion and desiccation when applied to cracks, baseboards, and under furniture. Its effectiveness diminishes on smooth surfaces and in the presence of heavy dust. Application requires a thin, even layer; excess powder must be removed to avoid staining fabrics. Safety guidelines restrict use around children and pets, and the chemical does not replace professional heat or pesticide treatments.

Combine visual inspection, proper luggage handling, and targeted use of boric acid where appropriate. Prompt laundering, heat exposure, and removal of contaminated items remain the most reliable defenses against bedbug transport.

Clutter Reduction

Boric acid works best when it can reach the insects directly. Piles of clothing, boxes, and furniture create barriers that hide bedbugs and prevent the powder from contacting their bodies. Eliminating unnecessary items flattens surfaces, exposing more of the hidden habitat to the treatment.

Reducing clutter also simplifies the process of applying boric acid. With fewer obstacles, applicators can spread a thin, even layer along baseboards, under mattress frames, and in cracks without the need to move heavy objects repeatedly. This consistency improves the likelihood that bedbugs will encounter the chemical during their movement.

Key benefits of a decluttered environment for boric‑acid‑based control:

- Enhanced visibility of infestation sites, enabling targeted application.

- Decreased hiding places, forcing bedbugs into exposed zones.

- Lowered risk of re‑infestation from items that have previously harbored insects.

Overall, a systematic removal of excess items directly supports the effectiveness of boric acid in managing bedbug populations.